The 25-Second Trick For Sheroz Earthworks

The 25-Second Trick For Sheroz Earthworks

Blog Article

Sheroz Earthworks - An Overview

Table of ContentsGetting My Sheroz Earthworks To WorkThe 9-Minute Rule for Sheroz EarthworksNot known Incorrect Statements About Sheroz Earthworks About Sheroz EarthworksGetting The Sheroz Earthworks To Work

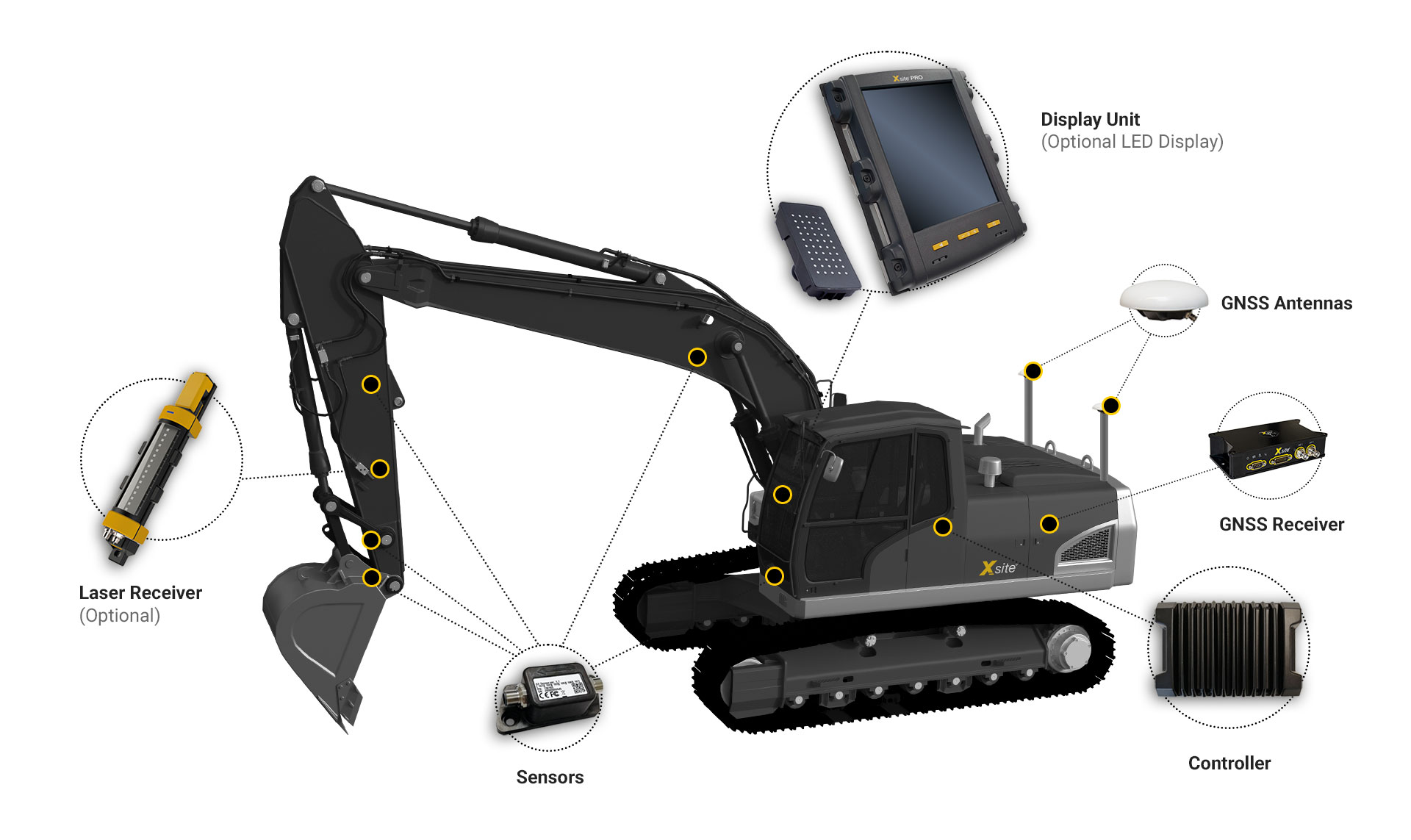

Below we offer a summary of device control and automation and rundown 5 factors why heavy building and construction can profit from truth capture, whether you are a driver, a designer, or a job proprietor. We normally divided device control right into 2 classifications.

The 3D design typically is available in the kind of triangulated surface designs or electronic terrain designs (DTM), which are uploaded using a USB stick in the situation of a single machine, or even more easily for several makers, using, a cloud-based platform for sharing data that can be managed centrally.

Fascination About Sheroz Earthworks

Maker automation does the very same calculations for the placement but has an added interface that takes some of the job out of the driver's hands. By making use of hydraulics or linking to systems on the device, maker automation can position the machine itself and fulfill the preferred worth, such as excavating to the appropriate deepness.

The trend in the industry is for advice systems to come to be increasingly more automated. The excavator system particularly has actually seen numerous advancements over the previous 12 months, including the semi-automatic excavator. https://www.abnewswire.com/companyname/sheroz.com.au_142204.html#detail-tab. We have drilling systems that can quit drilling immediately when the device control tells the system that it's struck the preferred deepness, and services for dozers and graders user interface with the makers' hydraulic system for an automatic procedure

Generally, device control requires some instruments to place itself, and there are a few ways of doing this. In straightforward cases, if you're just worried with height, for instance, you can utilize a turning laser. We describe this as a 2D machine control system. Secondly, you can utilize a complete terminal tor laser scanner to get setting and elevation, which holds true 3D device control.

Finally, the most common placing type for machine control is GNSS, which will certainly position the machine to 3D precision of approximately 30mm. In all these cases, the first positioning is not done to the setting of the device itself, so there are other sensing units mounted to transfer the position where the sensing unit remains on the rear of the device to the get in touch with point of the device.

The Single Strategy To Use For Sheroz Earthworks

They can check the precision of their own job and easily think of the ended up trimble gps item by looking at the model on the display. All this added information enables them to obtain the job right initially go, decreasing any rework. For the designer, device control implies that there are no pegs or batteries to knock in for hours at a time as the information is all there in the maker.

For that reason, the time that they require to spend near heavy machinery an usual location for accidents is lowered. Device control suggests that there's much less product waste as operators can be much more accurate in their job. This likewise indicates less gas is consumed, both consider aiding building and construction companies meet the job's environmental targets.

It's simple to establish your avoidance area and a trigger distance where the maker control system will alert the driver to risk. As soon as the equipment goes within the trigger range, the system sends a warning with a distinct alarm, and the display goes red. trimble gps. It's possible to obtain data back from the equipment control system in the type of gauged factors for the as-built coverage

Leica Geosystems' remedy for hefty construction applications uses a unified hardware platform with an usual software interface across our equipment control profile., while Leica ConX, the cloud-based and user-friendly efficiency platform for enhanced task effectiveness, rounds off Leica Geosystems' goal to attain a digitised building and construction site.

Not known Details About Sheroz Earthworks

It is obvious that there is a lack of fresh skill going into the industry. Specifically, contractors have trouble attracting youngsters and, as an outcome, there are less drivers getting in the career (topcon). Should this fad proceed, the industry will certainly be entrusted to a lack of knowledgeable and trusted drivers, which means that the quality and productivity of projects will certainly be affected by a substantial abilities gap

Little Known Facts About Sheroz Earthworks.

When looking at the current building and construction landscape, it is clear that, despite its substantial advantages, maker control automation is not being adopted throughout all makers at an equal price (https://sketchfab.com/sherozau). Although automation is being welcomed on machines like graders and dozers, the uptake has been much slower for excavators, with the fostering price of automated machine control on these devices still estimated at around 10% in Europe in comparison to a rate of over 50% for dozers.

Report this page